Bamboo weaving is an ancient craft that transforms humble bamboo into beautiful, functional art. The process involves several meticulous steps, each requiring a high level of skill and precision. Here’s an overview of the bamboo weaving process:

Step 1: Selecting Bamboo and Splitting the Strips

Selecting Bamboo

The first step is selecting bamboo that is 2-3 years old. Mature bamboo is both sturdy and flexible, making it ideal for weaving. Bamboo from the shaded side of the mountain is preferred because it grows in a more suitable environment, resulting in longer and thicker nodes.

Splitting the Strips

Once the bamboo is harvested, the next step is to split it into fine strips. This step is crucial as the quality of the strips directly affects the final product. Skilled artisans can determine the quality of the bamboo strips through this splitting process.

Step 2: Sizing, Smoothing, and Cutting

Sizing the Strips

To ensure uniform width, bamboo strips are processed through a special knife called “Jianmen Dao.”

Smoothing the Surface

The outermost layer of the bamboo, which may have blemishes and stains, is removed. This process, known as “scraping the green,” ensures a uniform color and enhances durability. Any bamboo with defects like dark spots or insect damage is discarded.

Cutting into Thin Slices

After drying and charcoal baking, the bamboo is cut into thin slices. The outermost layer is removed to eliminate the yellowish layer.

Step 3: Preparing the Strips

Making Strips

The thin slices are further split into finer strips using a chisel. These strips are then evenly sized by hand to ensure uniformity. Any imperfect strips are removed. The strips are carefully stretched and pulled to achieve the desired thinness and flexibility. Only the best strips, about eight ounces out of one hundred pounds of bamboo, are selected for weaving.

Step 4: Weaving

Weaving Techniques

The weaving process involves various techniques developed over centuries. The primary methods are flat weaving and three-dimensional weaving, with flat weaving serving as the foundation for more complex patterns.

Common weaving patterns include:

- Herringbone Weave: Resembling the shape of the letter “V,” it is widely used in bamboo mats, trays, and tea trays. The herringbone weave can be dense, making it versatile for various applications.

- Cross Weave: This method creates a lattice-like pattern and is often used for agricultural tools like bamboo sieves.

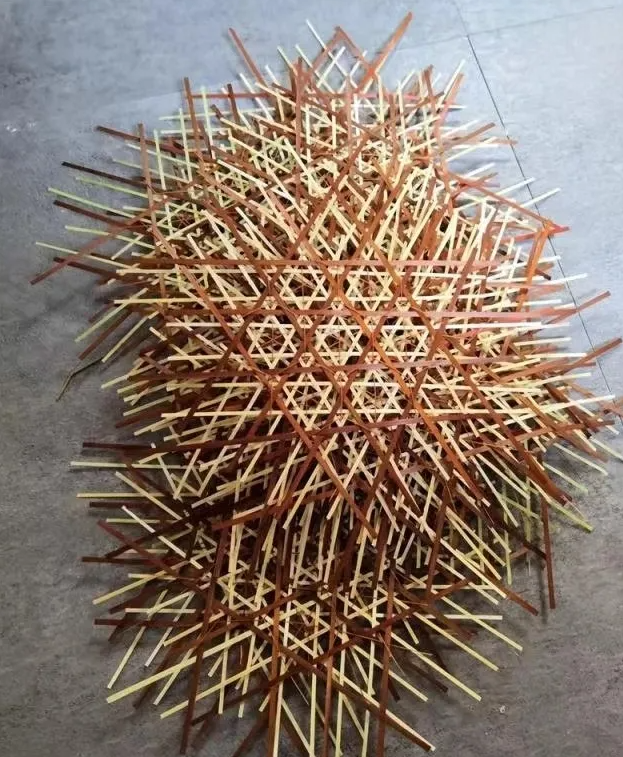

- Chrysanthemum Base Weave: This technique, often used as a base in porcelain bamboo weaving, radiates outward like a blooming chrysanthemum.

- Thread Weave: Producing snowflake-like patterns, this method can create intricate designs with single or double layers and various colors.

- Twist Weave: Known for its three-dimensional effect, this technique is frequently seen in high-end bamboo vases. Variations include pineapple, herringbone, loquat, peacock feather, hexagon, and square twists.

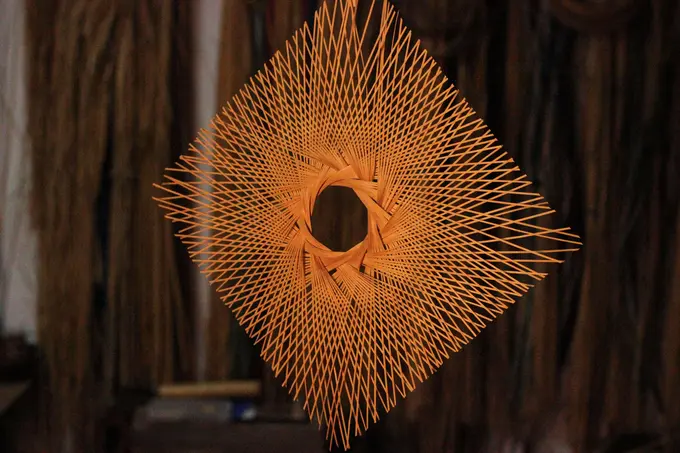

- Spiral Weave: Also called the chicken coop top, this method forms a hollow circular pattern. It is commonly used in bamboo lanterns and cricket cages.

Step 5: Final Touches

After weaving, the bamboo products are polished and finished to enhance their appearance and durability. Each piece is a testament to the artisan’s skill and dedication, preserving the rich cultural heritage of bamboo weaving.

By understanding and appreciating the intricate process of bamboo weaving, we can better value these beautiful, handcrafted works of art.